Roll formed pallet rack is made using cold rolled sheet metal while structural rack components are made with hot rolled steel.

A rack is made from roll formed sheet steel.

Roll formed pallet rack is generally less expensive easier to install and all around more convenient.

Rack manufacturers will commonly use the words cold rolled roll form rack or hot rolled structural steel.

The dimensions are indicated at the center thickness of each segment.

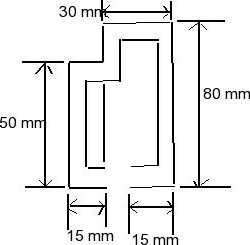

Figure 1 determine the location x y of the centroid of the cross section.

A rack is made from roll formed sheet steel and has the crosssection shown.

After the steel has been punched the.

Roll form cantilever rack towers and arms have a tubular steel design.

Structural steel is often more expensive but is also usually stronger and much more resistant to damage.

Roll form cantilever racks are for the storage and easy selection of pipe tubing bar stock and other long items where uninterrupted shelf levels are required.

The dimensions are indicated at thecenter thickness of each segment.

Suppose that l 1 45 mm and l 2 75 0 mm.

Since roll formed pallet racks are made of lighter gauge steel with boltless beam pin connectors they are less expensive to buy and install.

While it is flat the steel is processed through a punch that punches the holes which will later be used to attach the beams.

However roll formed racks can be limited in the amount of weight that they can support and they are more.

Structural rack is hot rolled structural steel and roll formed rack is cold roll formed steel.

Roll form rack starts as a coil of steel.